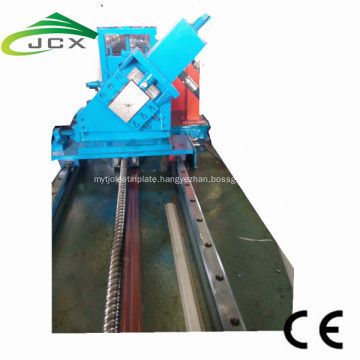

Galvanized H strip joint making machine

| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 45 Days |

| Packaging: | Coverd by plastic film |

|---|---|

| Productivity: | 30sets/Month |

| Brand: | JCX |

| Transportation: | Ocean,Land |

| Place of Origin: | China,Hebei |

| Supply Ability: | 30sets/Month |

| Certificate: | CE, ISO |

| HS Code: | 8455221000 |

| Port: | Tianjin,China |

Basic Info

Model No.: 23*17 h jointing strip

Click on the follow link to find out more information: https://www.jcxsteelrollformer.com/double-furring-ceiling-roll-forming-machine/

Company Info

- Company Name: Botou Golden Integrity Roll Forming Machine Co.,Ltd

- Representative: YANG JIE

- Product/Service: Roof Panel Roll Forming Machine , Cz Purlin Roll Forming Machine , High Way Crash Barrier Roll Forming Machine , Light Gauge Framing Machine , Roller Shutter Door Forming Machine , Double Layer Roll Forming Machine

- Capital (Million US $): 500000RMB

- Year Established: 2010

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 51% - 60%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 15

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: ECONOMIC DEVELOPMENT ZONE ,BOTOU CITY

- Contact Person: Mr. Jason Zhang

- Tel: 86-318-8189095

Premium Related Products

Other Products

Hot Products

Color Painting PVDF Aluminum Coil for Construction DecorationBlack Annealed Cold Rolled Steel CoilSs340 G90 Galavanzied Steel Coil ManufactoryGalvalume Gl Aluzinc Zincalume Steel Sheet in CoilChinese Supplier Color Coat Galvalume Steel Sheet, Color Coat Galvalume Steel Sheet in Coil with Lowest PricePrime Prepainted Galvanized Steel Sheet in Coil First Mill Price with Good Quality for Roofing Sheet/Gi/Gl/PPGL/PPGI/Steel CoilHot Dipped Galvanized Packing Steel StripHigh Quality Cheap Corrugated Galvanized Steel Sheet with PriceASTM A792 G550 Az150 Galvalume Steel CoilAngle Steel Q235 Grade Carbon Steel Angle Bar1.2 mm Thickness Ss400 HRC Hot Rolled Steel CoilPrime 0.45mm PPGI Steel Coil, Pre-Painted Gi Steel Coil0.22mm Thickness Mr SPCC Electrolytic Tinplate CoilQ235 Grade Slit Galvanized Steel Strip with SGS ApprovedHot Dipped Galvanized Corrugated Steel Roofing for BuildingASTM A653 Dx51d Grade Hot Dipped Galvanized Steel Coils