Omega steel profiles stainless steel channel roll forming machine

Basic Info

Model No.: CNZT-002

Product Description

Omega Steel Profiles Stainless steel channel roll forming machine

Omega furring channel is a hat shape corrosion-resistant framing component used to fur our masony walls ans celling assemblies. For concrete wall application, our product can be installed vertically along the wall surface via concrete nails or power-driven fasteners. Omega steel profiles stainless steel channel roll forming machine could be used to make the corrosion-resistant framing component in batch and fully automatically.

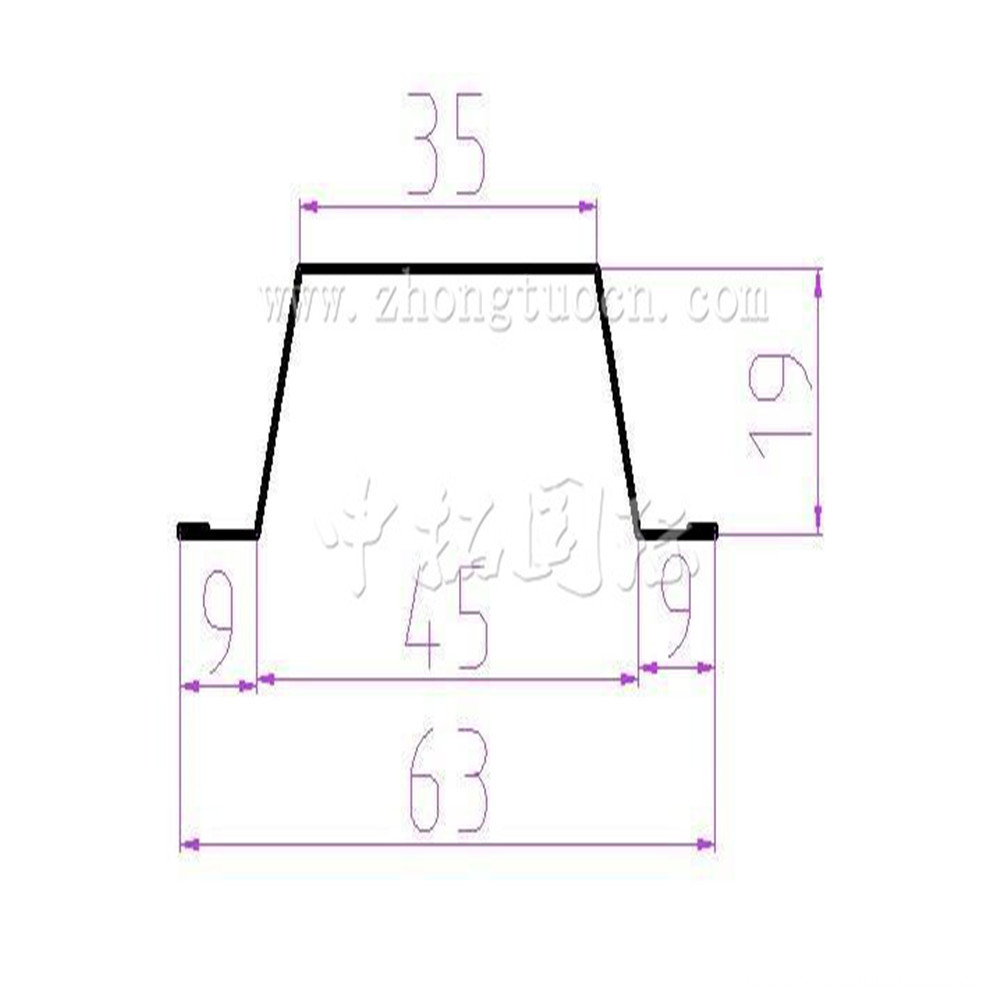

Drawing profile for you reference :

Component for Omega steel profiles Forming Machine:

1. Decoiler one set2. main roll forming machine one set

3. cutting and punching part

4. control box one set

5. hydraulic station

Details information for Omega steel profiles rolling machine:

Decoiler

Usage: It is used to support the Steel Coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 1.5T

Uncoiling width: 300mm

Inner diameter: 450-550mm

Main roll forming machine:

Feeding and leveling will level coil to make sure it is neat clean and straight.

Size: 3800х800х1400mm

Weight : 2.6 tons

Voltage:380V/50HZ 3Phase(as customer`s request)

Roller fixer : Guide column

Frame : middle plate welded Memorial arch frame type

Frame thickness:25mm

Speed: 5-50m/min

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ40mm

Number of rollers : 10rollers

Main power: 4kw

Processing flow diagram of machine

Manual decoiler→ Feeding material into machine →Roll forming machine →Measure length→Hydraulic cutting →Finished Products

Machine pictures for your reference

1.Technical parameters

| Configurations | manual decoiler, guiding platform, main machine of roll forming, cutting device, electric motor, hydraulic station, Delta PLC control system, run out table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material | Raw material | Galvanized | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thickness | 0.3-0.8 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Manual decoiler | Inner Diameter | 450-550mm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Outer Diameter | max 1500mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Max Coil width | 500mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Capacity | 3T | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main Forming Machine

| Forming steps | 12 rollers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Shaft diameter | 40Cr steel with quenched treatment, precision machined, outer diameter: 40mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Design type | Guide column | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Machine frame | Memorial arch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| roller material | bearing steel with quenched treatment | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| shaft material | 45# steel with tempering | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Work speed | 20-60m/min | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Transport | reduction gearbox transmission | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changing size methods | Completely changing the mold linear system | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Structure | independent stand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Power of main machine | 7.5 kw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type of cutting and punching | Hydraulic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cutting tolerance | ±1mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Blade and punching material | GCr12MoV quenching treatment 58-60° | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cutter quantity | 1 set | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Working pressure | 20MPA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Cutting system | Hydraulic servo tracking cutting | the machine is with servo tracking cutting, the cutting knife can move automaticly with the speed of the machine. so that, the tracking cutting can keep same speed with the main forming speed, and cut the finished products without any stopping. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2. Automatic tracking cutting

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Control Device | PLC Control | Speed regulation control cabinet | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PLC language | As required | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Touch screen | Delta | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Function | Automatic length and quantity measurement | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Other Spare part | Weight | About 8.0 ton | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimension | 6800*1800*1500 (mm) L x W x H | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main body color | As required | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Voltage | 380v, 50Hz,3 phase(or as required) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Spare cutting blade | One piece for one size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machine pictures for your reference

1.Technical parameters

Shearing machine:

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electic Control System:

Feature:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Hydraulic Station:

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine